Methods and Instruments

Zustandsbeurteilung Starrer Endoskope

Methoden und Instrumente für das opt. System

| Determining the Condition

of Rigid Endoscopes

Methods and Instruments Zustandsbeurteilung Starrer Endoskope Methoden und Instrumente für das opt. System |

|

| After a certain period

of use rigid endoscopes become dull which means that the former brilliant,

clear and precise picture impression has deteriorated. The image appears

dull and milky. Various parameters which determine the picture quality

apparently change within a certain period of time.

The manufacturers see

the cause for such dullness usually in mechanical damages of the lenses

of the optical system. This evaluation is also often confirmed by the damage

of the outer tubing. Such damages often lead to damages of the optical

system i.e. cracked lenses and therefore resulting in a change of relevant

optical qualities (focus, contrast) as well as the reduction of picture

brightness (decline of transmission). This evaluation is surely correct

and comprehensible.

But besides mechanical influences which can damage an optical system there are also wear and tear factors which can influence the picture quality just like a broken lens. These coherences are not named very often in case of repair. Since the amount of the repair is substantially influenced by whether a lens is cracked or not, there is a demand for a method to test the condition of optical systems of rigid endoscopes at hospitals. |

Starre Endoskope trüben nach einiger

Betriebszeit ein, d.h. der ehemals brillante, klare und scharfe Bildeindruck geht verloren. Bilder werden als trübe oder milchig eingeschätzt. Verschiedene, die Bildqualität einer Optik bestimmende Parameter, verändern sich offenbar im Laufe der Zeit. Als Ursache für das Auftreten

von

Neben mechanischen Einflüssen,

die eine

Da es von nennenswerter Bedeutung

für die

Fortsetzung.... (German text) |

1.

Introduction

2.

Basic Construction of Rigid Optics

3.

Behaviour with Bending Stress

4.

Testing Methods of the Optical system

5.

Summary and Evaluation

Depending on the location of damage inside the inner endoscope – within or outside the area of arranged rod lens made of optical glass - the optical system can be effected or not by mechanical influence. So damage with the jacket tube might cause optical impairment. It might not, if damage is within an area of relative distance to an arranged rod lens. In this case there might be no loss in optical quality.

The absence of obvious outer visible damage of the jacket tube does not exclude breakage of the inside lenses, as mechanical stress of the jacket tube could always take place in the elastic region, whereby an optical glass located within a visibly damaged area will be effected.

In conclusion, the visual test of the jacket

tube of the rigid endoscope is no adequate method of evaluation, concerning

the condition of the optical system. Although different causes, both appear

as a foggy image. In order to prove costs of repair it is necessary to

know and name the exact reason of damage.

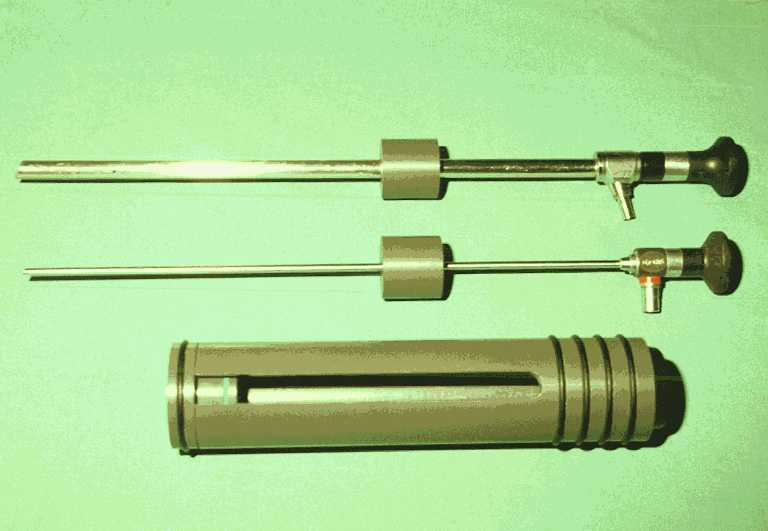

The lenses of the optical system are arranged in the inner tube, and held in place with distance pieces. The distal region of the inner tube is closed by the deflector prism (that determines the direction of view) and with the eyepiece at the proximal part. The inner tube is enclosed by the jacket tube containing optical fibre cable and it`s connector.

The jacket tube has a covering lens at the distal part and an ocular at the proximal part. One of its significant attributes of the jacket tube is the ability to seal against invading substances.

Fig. 1: Parts of a rigid endoscope

Top: Jacket tube (enclosing

fibre cable), connector for fibre cable and outer eyepiece

Middle: Inner tube with

eyepiece

Bottom: Deflector prism

with (some broken) optical lenses and distance pieces

Damages of the lens margins are often unnoticed. These damages often lead to discussions concerning costs of repair. The argument is: "The endoscope was not foggy. I would have noticed - so a breakage of the lens is not likely."

A massive lens breakage can be seen on the cover. Such damage cannot be overlooked. The endoscope is foggy.

As stress behaviour of rigid endoscopes is not the issue of this article, I would like to avoid further discussions.

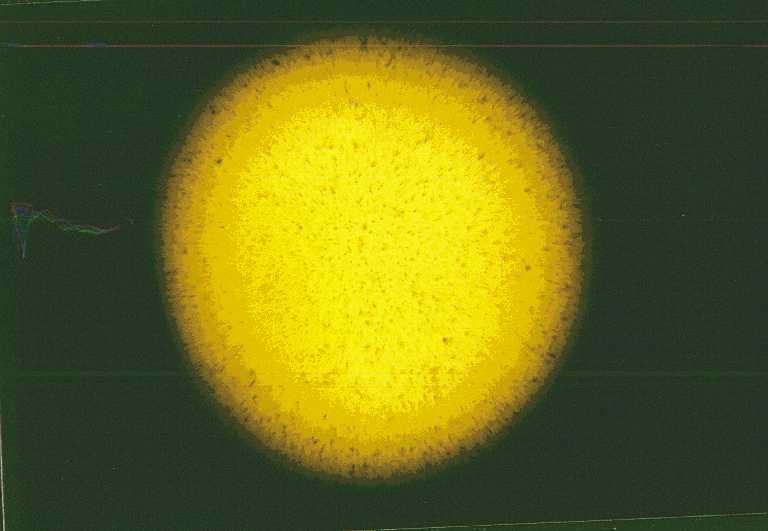

Fig 2: Broken lens in the margins

I would like to introduce the methods of evaluation conditions of the optical system. Beyond that, there are no other methods used within this field, or externally by third persons, as far as I know.

4.2 Measuring of Transmission

This is a method determining transmission

of the endoscope. A luxmeter is adapted to the eye piece of the endoscope.

At the distal part light is directed through an adapter, the proximal output

represents the data.

This device has to be calibrated first because of the light source efficiency, the loss in the optical fibre cable and the adapter. This reference data is defined as 100%. Interposing an endoscope as a measuring object between light input and measuring instrument, there will be a natural loss in light density. In proportion to the reference data this is defined as the individual quality criteria.

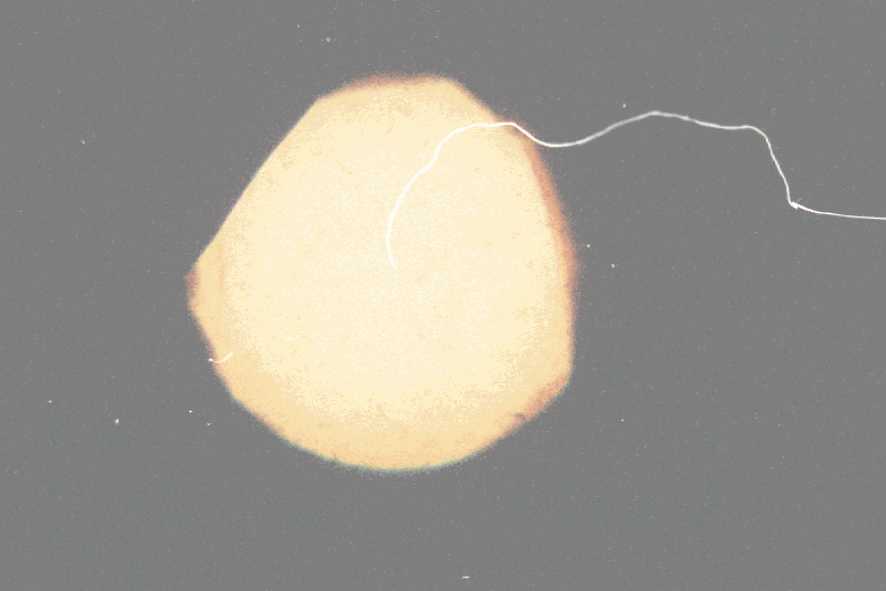

Fig. 3: Typical view of a foggy lens (caused

by wear and tear factors)

Transmission of an endoscope is determined by measurement sequences. Further measurement sequences determine the point of loss in transmission, which is the indicator for impairment of the endoscope. The typical inside view of a foggy optic is shown in fig. 3.The disadvantage of this method is the measurement expenditure, and the necessity of working out and determining limit values. Apart form this, it can be regarded as a suitable method to evaluate an approximate condition of the endoscopes quality. It is not suitable to prove breakage of the lenses. It is only the result (fogginess) of a lens breakage that is measurable.

As this measuring instrument can also be

used for measuring light source quality and fibre light cable quality using

complying adapters, the costs of DM 1.700,-- are worthwhile. The method

is analogue to endoscopes` measurements. A loss in transmission can be

determined using the reference data.

4.3 Testing Method with the Magnifying

Glass

This testing method of the optical lens

system is known, but not described, as far as I know. Using a magnifying

glass the endoscope is held against a bright reflective surface in order

to inspect the endoscope through the eye piece. This is possible, if the

optical axis is identical with the ones of the endoscope and the magnifying

eye. By varying distance between endoscope and eye (keeping the axial plane),

it is possible to look inside the optical system and inspect every single

lens. Focussing one lens surface, deposits can be noticed or dismissed

if there are none. Also lens breakage can be proved. This method requires

a lot of practice, as getting the optic axis in straight line with the

axis of the endoscope gets more difficult with increasing distance to the

eye, and also with increasing length of the endoscope. The tester quickly

gets tired, as well because of blending side effects caused by reflection

and the lateral incident angle of light. This method is unequivocally useful

to observe lens breakage. Also deposits caused by wear and tear can be

observed and differentiated from lens breakage.

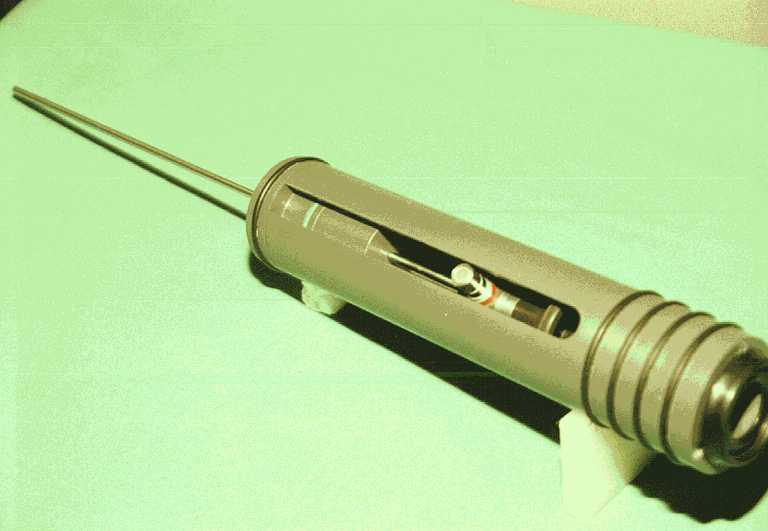

4.4 Testing Method with the Monocular

Tube

This method is the development of the

magnifying glass and can also be used by semi-skilled staff. The endoscope

is inserted into a jacket tube containing an integrated magnifying glass

at the proximal end. A distance piece, gliding over the jacket tube centres

the telescope within this construction (fig. 4/5). By varying the distance

between magnifying glass and the eyepiece, different depths within the

endoscope can be focussed. Variation in distance is achieved by gliding

the endoscope within the construction.

This script introduces different internal and external methods of determining quality of rigid endoscopes. The transmission measurement method, as described in 4.2 is appropriate to the technician who wants to evaluate the ageing process concerning loss of transmission. The following results can be achieved: after x sterilisation cycles with method y, the endoscope 4711 lost z% in transmission. As shown above, these statements can also be achieved with other optical instruments. An indication of the endoscopes` life service (usually defined as the number of sterilisation cycles before becoming foggy) can be given.About the Autor:The Monocular Tube being the developed magnifying glass is no appropriate method of measurable criteria of quality, but it allows a quick check concerning the grade of fogginess and proving or excluding a lens breakage. This method is practicable in hospital and whenever doubts occur concerning classification of costs. Being able to differentiate between ageing influences and improper handling, possible guarantee claims towards the manufacturer may be made. This is a direct economic advantage. With increasing experience, quality of repair, especially done by a third party can be proved.

The construction of the Monocular Tube is small, handy, can be used anywhere and is not dependant on an energy supply: after surgery, in the room of disposal, or before sealing with sterilisation foil. It is a useful method for the premium check of condition, before sending in for repair, and it also is an aid for the representative. Lens breakage and ageing influences can be proved and determined. A differentiation between proper and improper handling can be made.

Regarding the sum of $ 2500 or with a stock of more than 5 endoscopes, the purchase of at least one of both measuring instruments should be considered, or in very rare cases, training for the magnifying glass measurement method.

Dipl. Ing. Claus Hilger

Keuloser Str. 75

D-36093 Kuenzell

Claus Hilger is an consultant in medical

devices and is working for jurisdication and insurances (Additional

information in German).

Aditional Links: